There's been a philosophy of unrivalled craftsmanship at Bentley ever since the company was founded on July 10th 1919 by W.O. Bentley.

Today, this can be seen at the Bentley factory in North-West England town of Crewe, where craftspeople highly skilled in their trade are creating Bentley cars by hand. It is also on display at the Mulliner workshop, where numerous unique bespoke cars are being assembled.

Here at Grange, we have looked into the elements which have been behind Bentley's century of unrivalled craftsmanship.

Leather

The sense of comfort and refinement within every Bentley car is largely responsible for the leather hides that are carefully chosen for the interior design. You will not find plastic leather substitutes in any vehicle built by Bentley.

The numbers associated with the leather hides used on Bentley cars are impressive too. An estimated 15 leather hides are applied to every Bentley Mulsanne, around 14 in the Bentayga , another 13 in the Flying Spur and between 10 and 11 in the Continental GT depending on the body style selected. Consider that it takes 26 hours to cut, stitch and trim the seats found in each Flying Spur car alone.

Marquetry

Marquetry, the process of setting imagery into veneers and one of the oldest art forms seen across the globe, is often a highly skilled craft reserved for antique jewellery and historic buildings. However, Bentley has worked with its personal commissioning service Mulliner to create bespoke marquetry.

Modern techniques are used during this process, as well as a variety of exquisite materials which range from the entire spectrum of wood species and contemporary materials such as carbon fibre to more exotic materials like gold and mother of pearl.

Paints

More standard colours are offered by Bentley than at any other car manufacturer, with each tone expertly selected so that it perfectly complements the unique design of the vehicle concerned.

Mulliner also works to take the colour craftsmanship at Bentley that extra step further. This is because Bentley's personal commissioning service uses a digital colour matching facility to present drivers with a near-limitless selection of colours. If you provide Mulliner with a sample of your desired hue, the colour can be replicated in everything from the car's exterior to its hides, stitching and intricate interior.

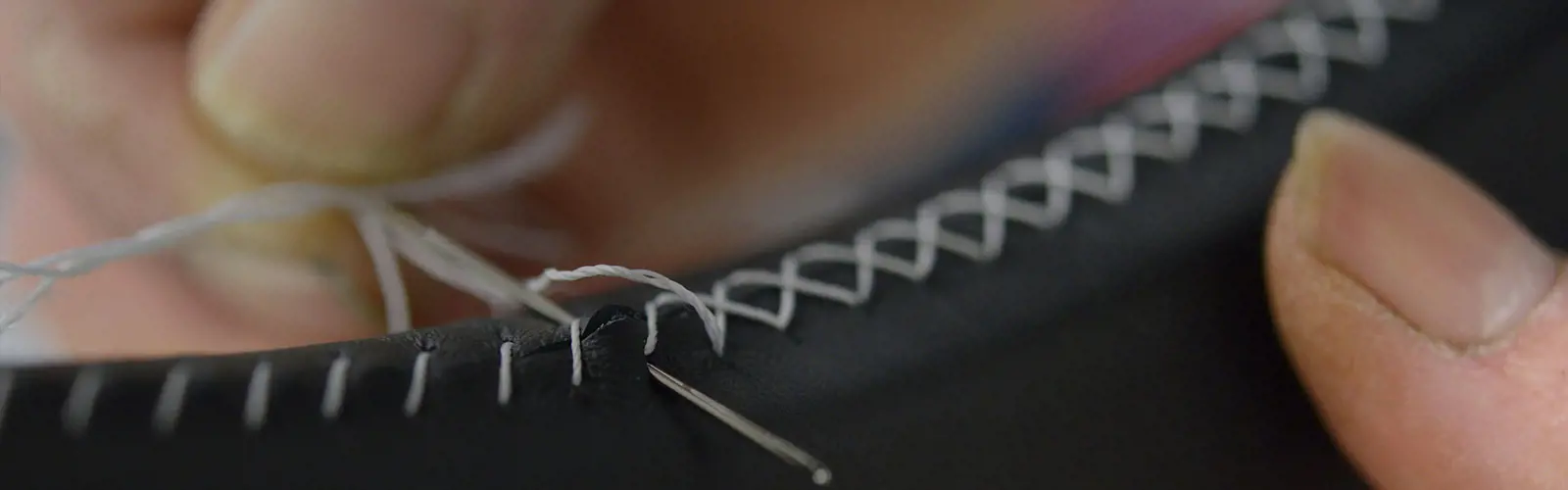

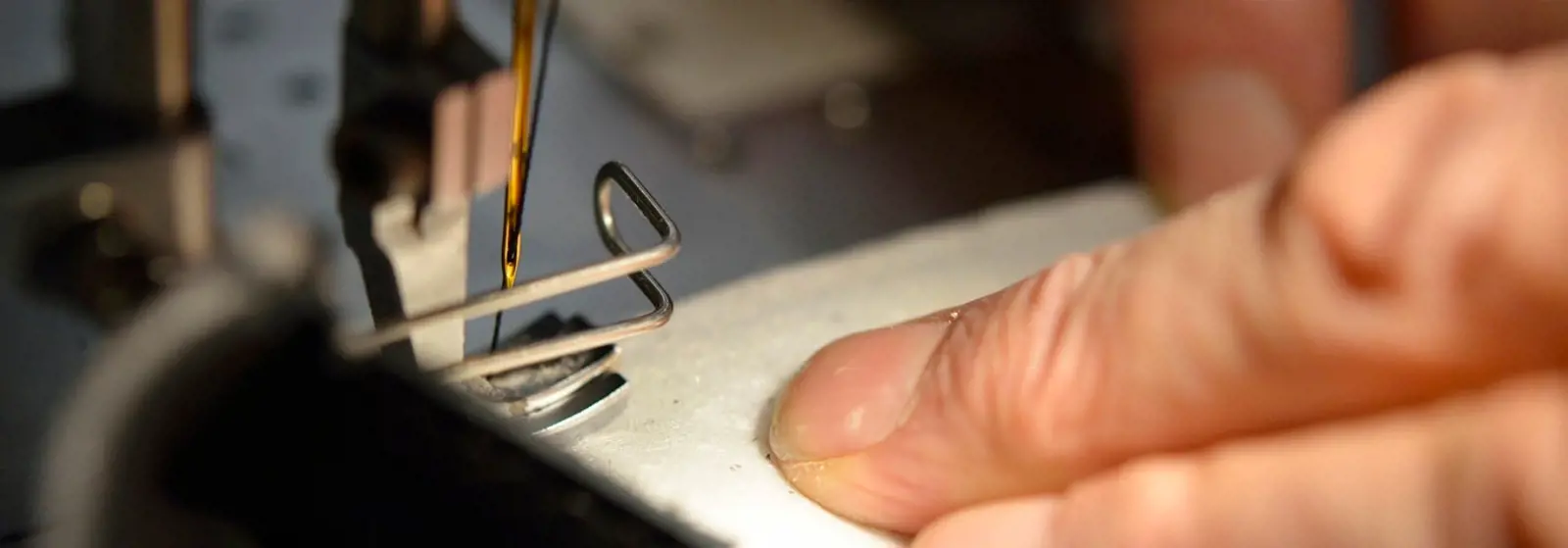

Stitching & Embroidery

To ensure an exquisite finish of the interior of each Bentley car, a lot of the stitching and embroidery is carried out by hand. In fact, 136 hours is needed to complete the interior of a Bentley Mulsanne alone. You can benefit from bespoke embroidery too, with around 500,000 individual stitches available on some designs - including a few truly bespoke colours.

Veneers

Step inside a Bentley car and you're sure to be impressed by the ring of veneer that encircles the vehicle's cabin. It's a striking feature, which is made possible by craftspeople at Bentley using a process called mirror-matching - sheets of veneer from the same section of a single tree being joined to create a sense of symmetry. Once fitted to the interior, this veneer creates a continuous grain pattern that surrounds the driver and passengers alike.

Veneers offered by Bentley for their cars come from trees which are grown worldwide, ranging from bespoke choices like paler, straight grain species to the rich, smoky grain of Dark Stained Burr Walnut.

Rest assured that every sheet of veneer Bentley uses is ethically sourced, as well as the fact that a tree will only be used if it falls naturally. Bentley even takes the time to plant a new one in its place in each of these instances. What's more, it takes one of the brand's wood specialists time to view around 25,000 square metres of veneer on average before a selection of the finest material is made.

Bentley is also consistently experimenting with new materials and techniques for its veneers. The Côte de Genève console veneer - inspired by Swish watchmaking - was applied to the new Bentley Continental GT, for example, while carbon fibre can be commissioned to give a car a contemporary and motorsport-inspired feel.

Explore our Certified by Bentley cars